Sam Maloof

Are you the type of woodworker that wants to make it big? That is, have clients waiting for months from a piece from you; will pay the price you ask, and be featured in magazines? Many of us aspire to be; I know I do. Some of us are just content making nice things for ourselves and family. Nothing wrong with that. The guys that do well in this business are far and few between – at least it seems that way to me. Not that there isn’t a lot of talented guys out there, there certainly is. I’m speaking of the guys in the vein of a Sam Maloof, James Krenov or even Kevin Rodel. I have an aspiration to be in that league. Let me make it clear – I’m not “making it big” right now in woodworking – either in standing or monetarily; but I am continually working my way up, improving my skill sets, and wanted to share what I am doing – and trying to do – with you.

Like all professions, successful people in this field have certain traits and skill sets that, in my estimation at least, take them to the very top. In fact, it’s a pattern, of sorts; if you follow this pattern, you too may find yourself on top of the woodworking world. What I’ve listed below is probably not all-inclusive, but I think it does speak for a great part of that pattern I spoke of.

Originality. A lot of guys can take a plan and make a good piece from it, just as competent musicians can play great established tunes; but a great woodworker will be able to design a great piece, and carry it out, just like Lennon and McCartney wrote good songs and performed them. Plainly put, if your design stinks, you’re going nowhere. Would we have heard of Sam Maloof without his rocker, or Krenov without his cabinet? Maybe not – they may have been just another very good – but not great – woodworker. Charles Limbert, Greene and Greene, Charles Rennie Mackintosh – all took from the Stickley Brothers; they designed along the same lines, but put there own design flair on the craftsman style.

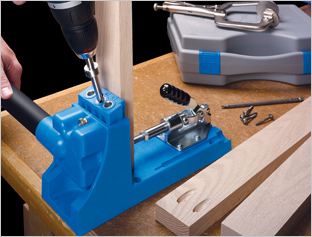

Technical skills / Perfection. You need to be a proficient, if not an excellent, skilled craftsman; if you’re not, don’t bother selling. I’m not saying you need to be able to hand cut blind dovetails, build award-winning federalist furniture, or be skilled in the way of the Jedi Masters, but you need to have a piece that has solid joinery, and a very good, if not great, finish – at a minimum. Be proud that your name is on that piece of work. Personally, I try to be a perfectionist, at least in areas of a piece that are readily seen. If not, and that piece is going to be in my eyeshot, that little imperfection is all I’ll ever see on that piece, even thought it may be a great piece otherwise. In fact, I find that I have to not look at the piece for several months (if not a year or more), then go back and look at it, with “fresh eyes”, and re-evaluate it again, before I can say, “Yes, that one’s ok.” Aim for perfection.

Passionate. You need to show you have a zeal for woodworking. How do you expect others to get excited about your pieces, if you don’t? So how do you show passion? Well, you can show it in your descriptive text concerning the piece, or when you are showing it to a possible patron.

Photography. What good is building a great piece, if you have crap photography? I see so many guys with just abysmal photography. A white bed sheet draped over your couch as the backdrop, and a cheap cell phone camera, seriously? I get you may not have decent equipment or be trained in how to take a good photo – nor do you wish to learn how to do so – but get somebody who can. Maybe a photography student from a local college that is looking to beef up their portfolio. Doesn’t your piece deserve to be presented in the best manner possible?

Marketing. Forget craft shows, unless you just want to sell cutting boards, or other cheap items. Let’s face it, there isn’t, unfortunately, a big market for good woodworking. You need to leverage the power of the Internet, because a national, if not international market is required. My advice? Yes, you can have your own website – and not spend much, if any money; just use WordPress for your platform. Alternately (or in addition to), get an account at CustomMade.com. I’ve done fabulous on that site, and their fees are decent. I don’t see any benefit of selling thru a retail location on commission (seriously, you want 50% of my take? I’ll give you 20% max; you’re putting no money into stock, just a little space in your shop; sorry lady). Etsy is ok, but that’s very much a craft woman’s place. It’s not much for expensive furniture, though smaller wood pieces do ok.

A Story. People love to buy into a story, whether it be the piece, you, or both. I’m not saying you have to write Moby Dick, but give the people something for their imagination to bite into. Here’s an example of what I mean, for, let’s say, a mantle clock:

Small craftsman clock, all maple, from a classic Stickley design. 17″ x 12″ x 5″.

Snooze. Now how about this….

I took the design of this clock from a piece I viewed at the estate of George Eastman, founder of Kodak. I asked the curator to let me take photos of it for design purposes. The wood used for it was actually from a tree that was blown down in a storm from his estate’s property, right here in Rochester NY.

So, which is more interesting to you? Same clock, different description. As for yourself, can you add anything? Something like this, perhaps:

My shop is located at the base of Whiteface mountain, in the Adirondacks of New York state. I buy my lumber from a local sawyer, as I like to support the local economy. Wood crafting has been a passion of mine since my grandfather took me into his shop some weekends, when I was only 15, and together, we made some simple, but useful pieces. I still have a small side table we built together…

Or, would you rather have something like this:

Woodworking since 1989. I’m a mechanic by trade, but I do this on the side. My shop is over 1200 square feet, and I have all DeWalt power tools, and is in the Detroit area…

Well, do you see the difference? When people spend money on a quality piece – and let’s face it, the stuff the better guys make is several times more expensive then what you’d buy at a retail furniture store – they don’t want just a piece of furniture, but a story behind it as well.

Reputation. Having one helps – a lot. I’m talking about being in Fine Wood Working magazine, or on a show, magazine, or other prominent venue. This will come in time – if you are good. My mentor is such a man. He can have all the commissions he wants. Thing is, he doesn’t do practical pieces, like furniture, but he does art woodworking – sculptures and such. When you think about it, a great idea. For one, not many guys do it, and for another, clients who want art usually have a ton of dough to be able to blow on it.

So there you have it, my observations on how to make it big – or at least, bigger. If you have any ideas on this topic, I’d love to hear it.

I made the point, in my previous ShopNotes post, that a large part of what makes a person very successful – really, in any endeavor – is the ability to generate original ideas that are good. You’re not going to be hugely successful just re-doing what someone else has already done; you must be original to really stand out and be really succesful.

I made the point, in my previous ShopNotes post, that a large part of what makes a person very successful – really, in any endeavor – is the ability to generate original ideas that are good. You’re not going to be hugely successful just re-doing what someone else has already done; you must be original to really stand out and be really succesful.