Finishing. No, I don’t mean finishing the project, as in completing it, but rather applying stains or topcoats. It’s an interesting part of the project, because it can really make or break a project. Poorly, done, it can make an otherwise great project look amateurish, and just really ruin the beauty of the wood. Done well, it just sets the piece off wonderfully. Common problems are blotchiness (think cherry), drips and sags, orange peel, dust – and glue squeeze outs, where the now-dried glue prevents any stain or dye from penetrating, and sticking out like a sore thumb. Sure, you can try to sand it down, but then you’ll you’ll probably leave a depression, because you have to sand quite deep, as the glue seeps into the pores quite a bit. Ugh.

Finishing. No, I don’t mean finishing the project, as in completing it, but rather applying stains or topcoats. It’s an interesting part of the project, because it can really make or break a project. Poorly, done, it can make an otherwise great project look amateurish, and just really ruin the beauty of the wood. Done well, it just sets the piece off wonderfully. Common problems are blotchiness (think cherry), drips and sags, orange peel, dust – and glue squeeze outs, where the now-dried glue prevents any stain or dye from penetrating, and sticking out like a sore thumb. Sure, you can try to sand it down, but then you’ll you’ll probably leave a depression, because you have to sand quite deep, as the glue seeps into the pores quite a bit. Ugh.

I remember on my first big project, a mission coffee table, re-sanding the entire table three times because I screwed up the finish as many times, and I had to get it right; on the fourth try, I did. What a pain to sand into all those tight corners and tight spaces!

Finishing can be such a tough part of the job that there are actually guys out there that specialize in finishing, as in, they will professionally finish your piece for you. It’s really it’s own separate field, just as project design is. The type of wood must be taken into account, as well as the type of look you want – do you want to highlight the ray fleck in that quarter-sawn white oak, or play it down? Does your piece require a tough topcoat, or will a moderately hard one do? How do you get that glass smooth feel? And so many more issues.

As I’ve written in an earlier blog post (“Mistakes are Just Forced Opportunities”), mistakes can actually force you to be creative; however, when it comes to finishing, mistakes can be very costly – in terms of time. Stripping down a whole project can take hours, not to mention the good possibility of damaging it with sanding mistakes. It’s frustrating to have your project come out great up to this point, and a poor finish just make it look awful.

So I’d like to share a tip or two that hopefully will help you make that next project’s finish look great – and done only once!

Most people will complete a project, then finish it. With some projects, that’s fine – if you are painting it, for instance. However, if you run into a problem, such as drips or sags – found, of course, after the stain has dried – then all you can do is try to strip that particular portion of the project and re-stain or dye it; good luck with that.

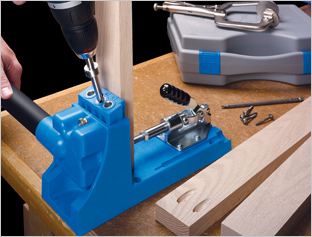

Here’s an angle you may have never considered – finish the parts before assembly. There’s several good reasons why:

- Easily strip and re-finish. Some time ago, I had a project that had ten ship-lapped boards on the back. I had applied the stain – carefully I thought – only to find that the stain had dripped down under a board, and onto another set of boards, hidden to me at the time. I found it the next day, after it had dried. Ugh. Tried removing it with solvent, but it looked blotchy; sanding was an option, but getting into the tight corners was almost impossible. The only solution was to remove the ship-lapped boards, make new ones, finish them and re-install them; looked much better. Had I finished them before installing them, and found a run (or other flaw), I could have easily seen and remedied it.

- Prevent glue squeeze out issues. Even being very careful, squeeze outs can occur, and they are a bear to clean up – even when fresh. You want to get a good amount of glue on the joint – and certainly not starve the joint of glue for the sake of preventing glue squeeze out. The solution is prevention all together. Usually, I use a paste wax finish on my projects now; it gives the piece a very smooth, buttery feel, and a nice sheen. The bonus? Glue, if squeeze out should occur, will simply pull right off the wax once it hardens. No need for a chisel or sand paper – maybe a little spackle knife, but that’s all. In lieu of wax, I use blue painter’s tape right at the edge of the joint where the pieces intersect, to catch any glue; this works very well. The painter’s tape leaves no residue either.

- Much easier sanding. Some guys will put the whole piece together, then sand. That’s often a mistake, as tight spaces make it nearly impossible to sand the whole board consistently. Sanding and finishing before assembly eliminates this problem.

- Try out new finishes safely. Ok, I’m guilty of this – trying out that new stain or finishing technique – on the finished, assembled project, and not liking it! Can you hear me, cherry? Instead, take a scrap piece from the lumber you used on this project, and try out that new stain. Maybe you’ll have to adjust the final grit of sandpaper, whether to use a sealcoat, or other issues, but try it out more safely.

Now some of you might object to finishing before you assemble, because you fear damaging the finish when you do assemble it. That’s a valid point. Also, you have make sure you don’t finish parts of the project that will be glued, as the glue won’t stick obviously on dyes, stains or topcoats. You simply have to mask off those portions to be glued, and be careful when you use clamps, perhaps using a soft, sanded wood block as a cushion on each end of the clamp jaws; speaking of which – some Jorgensen clamps (as i recall) have orange colored pads on their clamps that will actually ooze an oil out when clamped to your wood – meaning, you’ll have to sand it out. If your pieces to be clamped are finished, this shouldn’t be an issue.

So next time you have a project, try finishing it before assembly; I think you’ll appreciate the benefits.

Look, I’m a conservative, politically speaking, and even a year ago, if someone told me to “buy local” I would have rolled my eyes at the perceived long-haired dope-smoking liberal spewing that out to me.

Look, I’m a conservative, politically speaking, and even a year ago, if someone told me to “buy local” I would have rolled my eyes at the perceived long-haired dope-smoking liberal spewing that out to me.